Precision Tool Holder

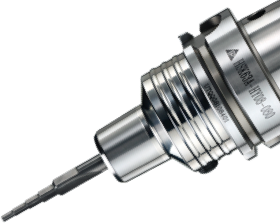

The tool holder is the key to connecting the spindle and the tool. Only with suitable tool holders under different processing conditions can it achieve the highest benefit with half the effort. We provide a full range of high-precision and high-quality precision toolholders with innovative clamping technology and mature and professional manufacturing capabilities. Providing the best solutions to meet the different needs of customers is our continuous goal.

Precision Tool Holder

The tool holder is the key to connecting the spindle and the tool. Only with suitable tool holders under different processing conditions can it achieve the highest benefit with half the effort. We provide a full range of high-precision and high-quality precision toolholders with innovative clamping technology and mature and professional manufacturing capabilities. Providing the best solutions to meet the different needs of customers is our continuous goal.

Our Quality

普慧刀把品質

| Material | hardness | Surface roughness | Cryogenic treatment | Taper shank accuracy | |

|---|---|---|---|---|---|

|

Steep Taper NiCrMo HSK / Premium Chucks Higher Grade | 55~58 Hrc Depth of Min. 0.8 mm | RA. 0.15 μm | 180 Degrees | AT3 or Better than DIN69893 |

| other brands | CrMo NiCrMo | 50~55 Hrc Depth of Min. 0.6 mm | RA. 0.2-0.4 μm | Nil or Only Sub-Zero (-90) | AT4 or Out of DIN69893 |

| Deflection accuracy | Grinding equipment | inspection method | Dynamic balance | ||

|---|---|---|---|---|---|

|

Same as Indicated in Catalogue | State of the Art from Swiss | 100% Checked with Certified Gauge by Trained Technicians | Actual Balanced with Balanced Machines | |

| other brands | Often Different as Indicated in Catalogue | Normal Grinder | Radon Inspection with Non Certified Gaugeby Non Trained Emplyees | Only Pre-Balanced but Claimed Balanced |

Cryogenic Treatment

The Austenite remaining inside the knife can be turned into Martensite, and its variable structure can reach 97% ~ 98%. The picture on the right is a metallographic diagram of two pieces of the same material but different heat treatment. If the knife handle is treated with cryogenic treatment, its life and stability far exceed those of untreated material. The company's products are HY, CR, PFC and so on.

Left | Metallographic diagram after ultra-cold treatment

Right | Metallographic diagram without ultra-cooling treatment

Precision tool holder series products

Deep hole machining・3μm high precision・Reduce tool wear

Shrink Fit Chuck

Shrink Fit Chuck

Quick tool change within 10 seconds・3μm high precision

Hydraulic Chuck

Hydraulic Chuck

Heavy cutting・5μm high precision・Super clamping torque

HER collet Chuck

Her Collet Chuck