company information

PARFAITE Enterprise's business spreads all over the world, from its headquarters in Taiwan to sales offices all over the world. You can view the contact information of all regions here.

About PARFAITE

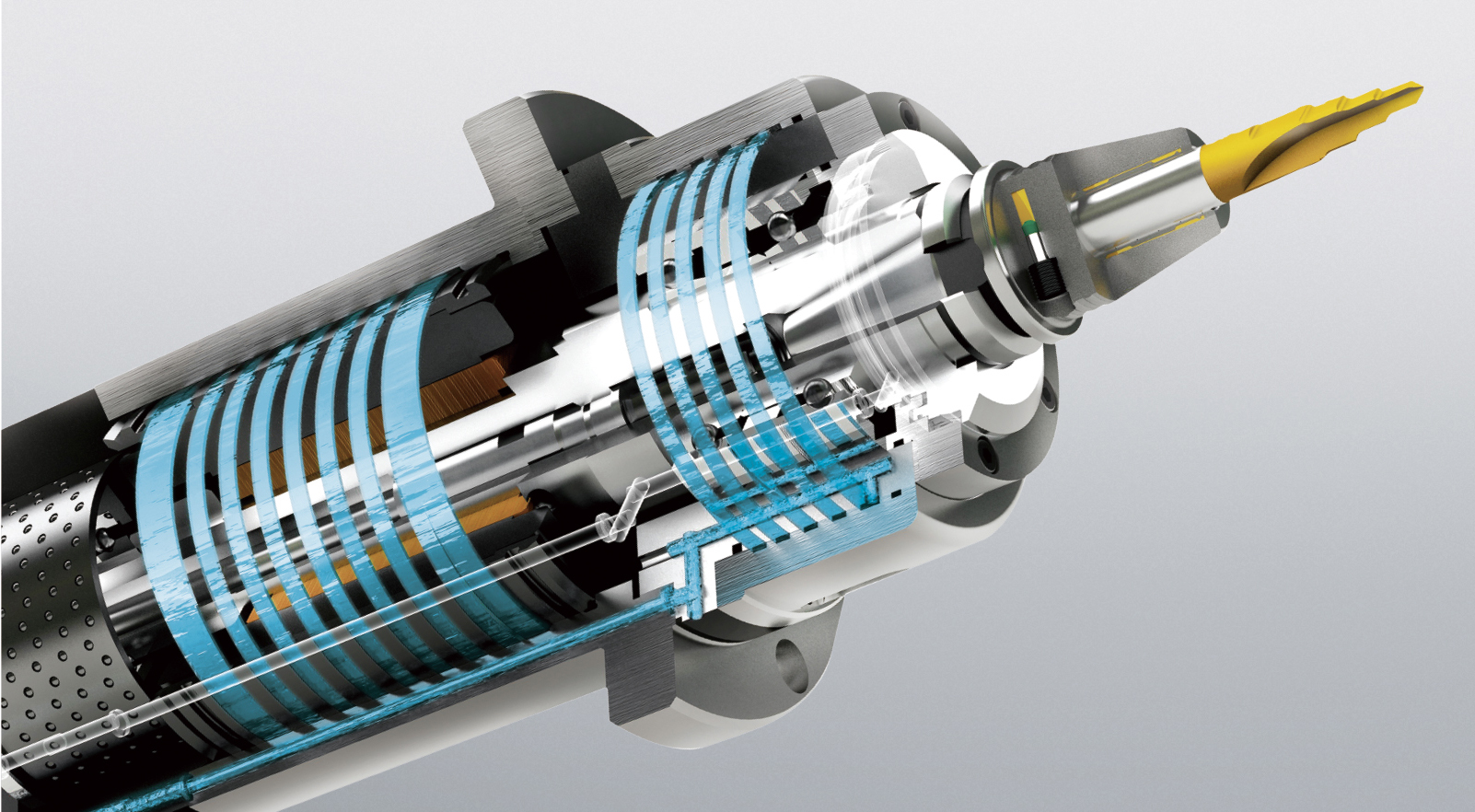

Established in 1982, PARFAITE Enterprise, based on nearly 40 years of mature and stable technology, specializes in the design, production and sales of high-speed motor built-in spindles, precision tool holders, and shaped tools. It is also the only company in the world that can produce this at the same time. A company with three high-quality technical products. In aerospace, machine tools, automobile and motorcycle parts, casings, molds and other production and processing aspects, ensuring customer quality is the highest indicator, and has been recognized by major manufacturers in the industry.

So far PARFAITE still insists on technological breakthroughs and innovations. In 1994, it successfully developed Taiwan's first high-speed motor built-in spindle. This move is an important target in the country. It will maintain this innovative spirit in the future and continue to improve in the industry. , And because of this insistence, whether it is customized products or more complicated processing procedures, PARFAITE can provide the most complete and professional services to meet customer needs, improve efficiency and quality, as requirements The highest standard of own products. It is believed that Puhui's new plant, which is about to start construction, will stimulate more unlimited potential.

For every product delivery, PARFAITE is not only simply repairing and shipping, but also looking forward to every interaction with customers, growing together to develop more diversified solutions, and fulfilling the needs of customers and the dynamic market.

──Wan Yukuan-Chairman

PARFAITE Spirit

The English name of PARFAITE Enterprise is "Parfaite", which means "perfect" in French. The design, production, and processing are all completed in its own factory, with a high degree of product accuracy and delivery. In the past 40 years, we have accumulated a solid user base in the fields of aerospace and automobile, with customers in Taiwan, China, Japan, Southeast Asia, Europe and the United States, and sales areas in six continents.

Why choose PARFAITE?

With many years of manufacturing technology and practical experience in the production of spindles, toolholders and tungsten steel forming tools, we can better grasp the processing problems faced by customers under various conditions, especially in the areas that can be solved by toolholders. You can provide machining targets and conceptual drawings. And other related information, we will discuss with you and evaluate suitable solutions to help optimize processing efficiency, improve production efficiency and reduce overall production costs.

What drives us to continue to evolve?

Processing is an endless process. PARFAITE produces 90% of products independently in the factory and can understand it in the same way as customers. Progress and improvement are the very important core indicators of all processing industries. Only continuous breakthroughs can gain an advantage in the competition, using advanced processing technology to overcome more diverse product processing, so PARFAITE hopes to provide its own experience to customers and grow together with customers.

PARFAITE product design process

PARFAITE focuses on product design and research and development. The first consideration is the demand for products in the market. Through many years of connecting with various processing industries, whether it is aerospace, automobile parts, green energy, precision molds, precision parts, 3C Products, etc., to explore more possibilities and provide products that enable customers to optimize processing. According to the special needs of customers, we provide tailor-made services. According to customer needs and usage habits, we can assist in the design of more suitable and efficient products, such as simplifying the processing procedures and designing holes that originally required multiple tools to process. A modular composite tool is developed to reduce the use of tools and improve the relative accuracy of processing.

Business Unit

Understanding customer needs through discussion

Product planning and discussion

Propose product specifications

Quality and Technology Department

Material application and processing conditions

Design proposal and make drawings

Engineer inspection and correction

Manufacturing

Strictly control quality

Make a detailed production plan

Complete customer high precision products