Clamping

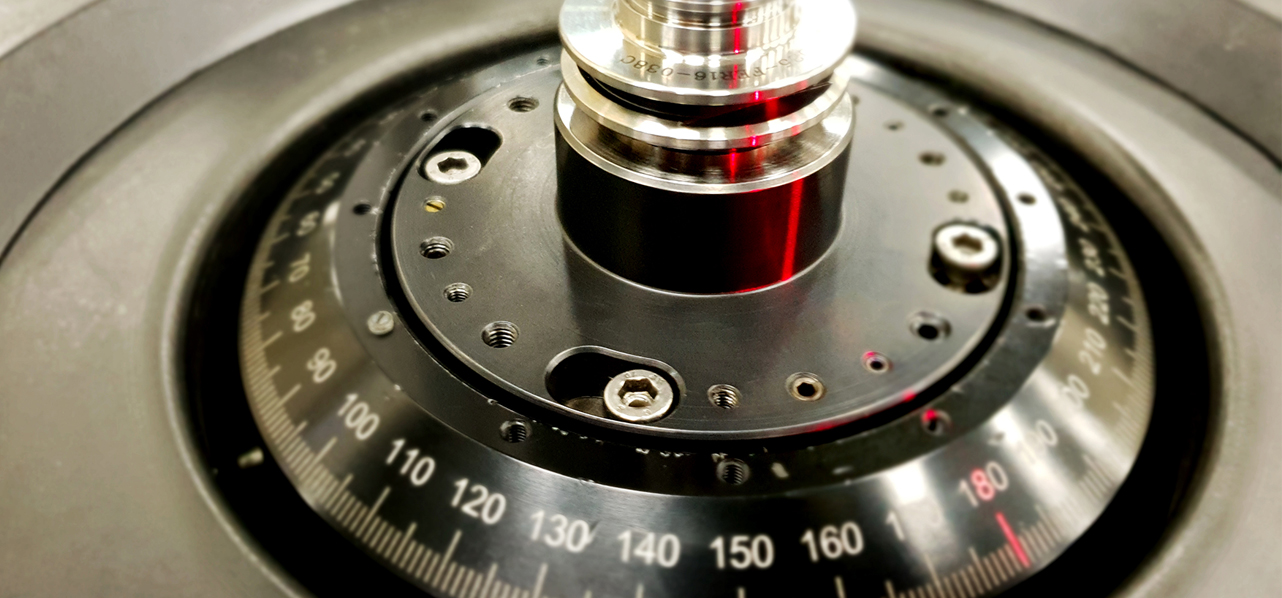

Clamping force

The clamping force of the tool holder refers to the clamping force of the tool holder to the tool, and its size can be measured in Nm Newton meters with a measuring tool. The higher the clamping force, the more tightly the tool holder can hold the tool, and the better rigidity makes it difficult for the tool to slip or loose when the cutting conditions are more severe, resulting in a situation commonly known as "tool drop". In other words, according to the different cutting conditions, a tool holder with sufficient clamping force should be selected to ensure the processing quality and the life of the tool and the machine spindle.

The importance of clamping force

Protect the life of the machine spindle

Under the condition of insufficient clamping force, the more severe processing conditions will cause greater vibration. This kind of vibration will cause significant damage to the bearing at the front end of the spindle of the machine. In addition to the significant reduction in bearing life, it also affects the accuracy of the spindle. Especially in an environment where high-speed machines are becoming more and more popular, the tens of thousands of maintenance costs and downtime losses due to insufficient clamping force caused by the early end of the spindle bearing life will be very significant.

Ensure the surface roughness and machining accuracy of the workpiece

Under the condition of the same conditions as the clamping accuracy... etc., a tool holder with insufficient clamping force may cause poor surface roughness or poor accuracy of the workpiece due to the above-mentioned vibration. More importantly, due to insufficient clamping force and excessive cutting force, "tool drop" and Z-axis size changes cause irreparable damage to the workpiece.

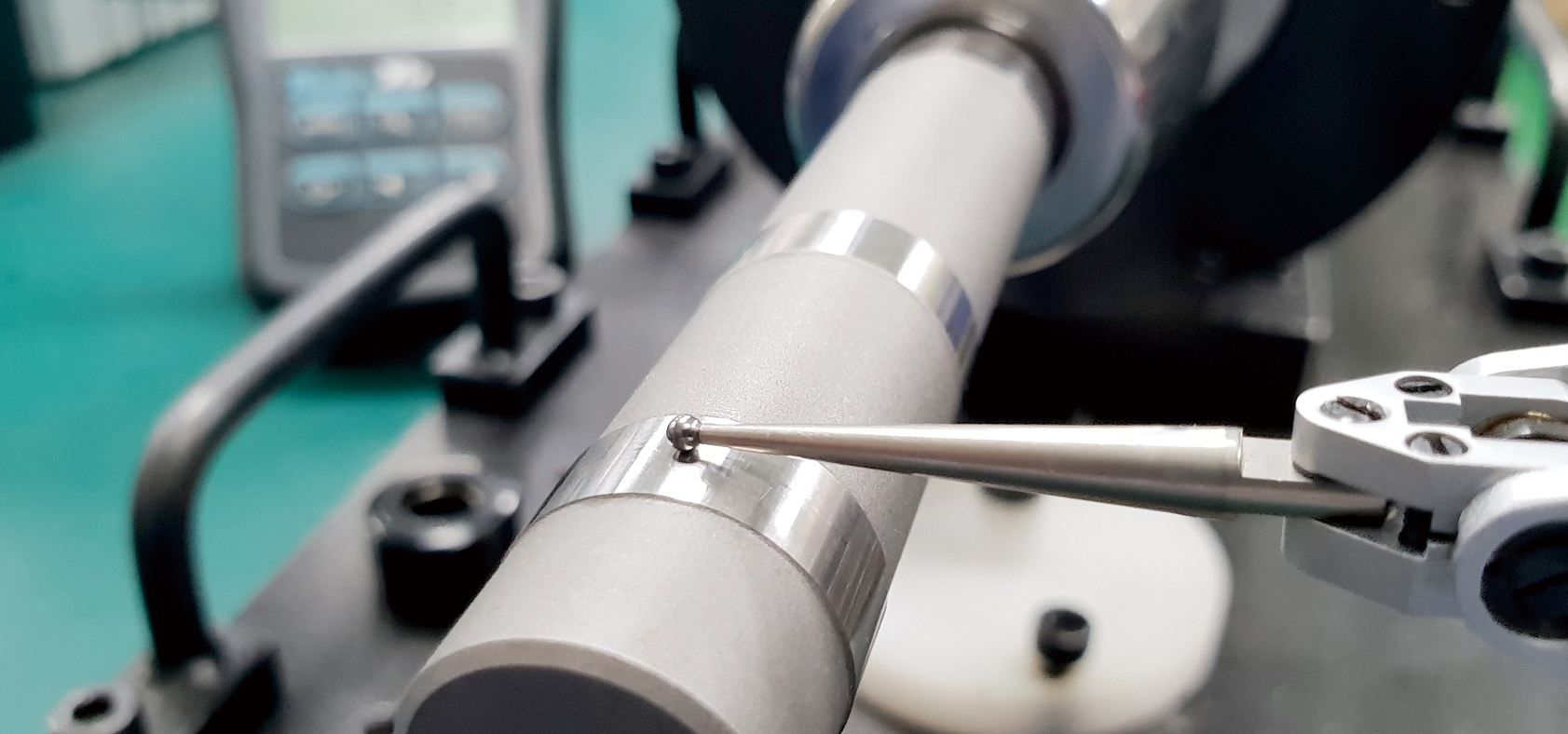

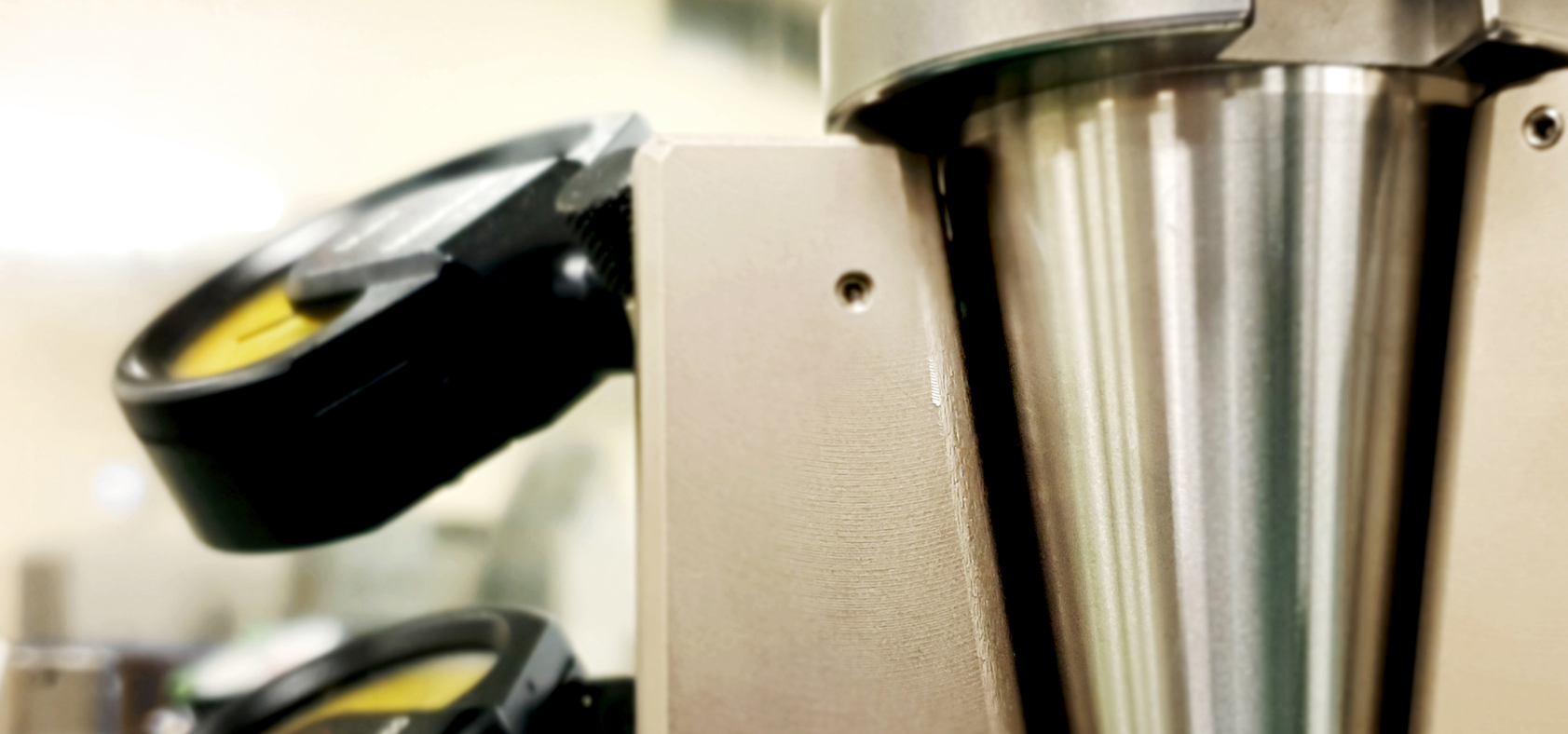

Protect and extend tool life

Under the same conditions as the clamping accuracy..., a tool holder with insufficient clamping force will cause abnormalities and accelerated wear to the tool due to the above-mentioned vibration, and the entire tool will be damaged and used. The clamping force of the tool holder varies with different clamping methods. For example, the clamping force of the PFK type tool holder with a 4-degree unilateral design is much higher than that of the ER collet with an 8-degree unilateral design. . The clamping force of the tool holder with the same clamping method is different due to the different manufacturing methods and know-how of the manufacturer. For example, the hydraulic tool holder manufactured by PARFAITE has a clamping force with an inner diameter of 20mm, which is higher than other brand oils. The pressing handle is about 40%. PARFAITE recommends that in addition to purchasing a tool holder with sufficient clamping force, a tool with a shank tolerance of h6 or more should be selected in the selection of tools to ensure the realization and maintenance of the overall clamping force.