HER Collet Chuck

HER collet Chuck

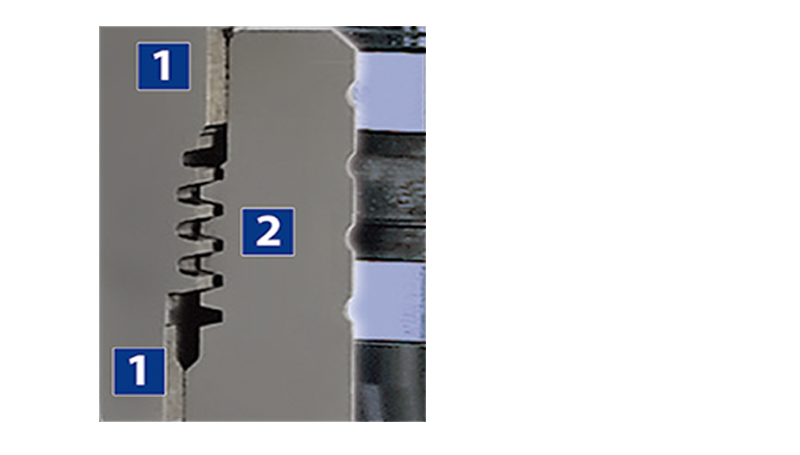

The power of trapezoidal threads

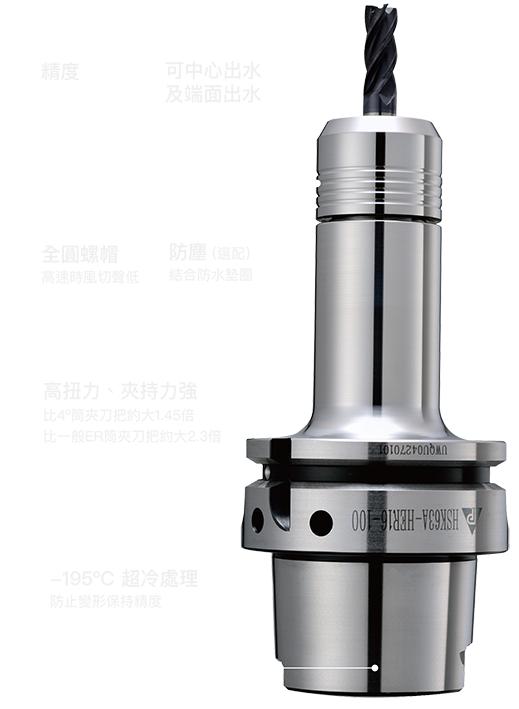

With high rigidity 200Nm super clamping torque and 5μm yaw and high precision characteristics, it is a high-efficiency tool holder that can be used for heavy cutting and finishing. The clamping torque is 2.3 times larger than the general ER tool holder. The depth of cut and feed efficiency can be optimized.

Heavy cutting

High rigidity and high clamping force can optimize the depth of cut and feed efficiency

5µm high precision

Deflection runout≦0.005mm

Super clamping torque

High rigidity and high clamping force (230% higher than general ER), suitable for various rough/medium/finish processing

Reduce tool wear

Increase surface roughness and reduce tool wear

Long life

Protect tool spindle and extend equipment life

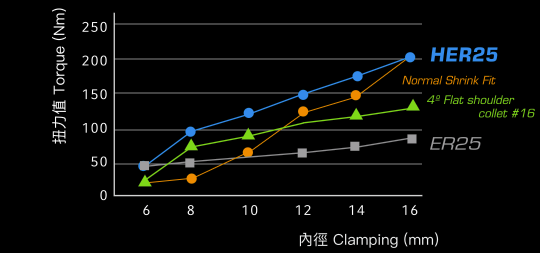

Comparison of clamping torque

The clamping force of HER25 is better than that of heat shrink, single-sided 4° flat shoulder collet and traditional general ER collet system. Take HER24 as an example: When the inner diameter is 12mm, the clamping force is about 145% larger than the 4° collet, 130% larger than the general heat shrink, and 230% larger than the general ER tool holder.

Super perfect accuracy

The special structure of the double-length super-long guide rail [1] and the trapezoidal screw thread [2] can form the transformation force of penetration and reduce the friction force. Therefore, when locking, ensure that the nut is in the center of the handle There is also a perfect load. There are other advantages of high clamping force, high concentricity, and high repeat accuracy. At the same time, the short thread design also saves the time of assembling the tool holder.

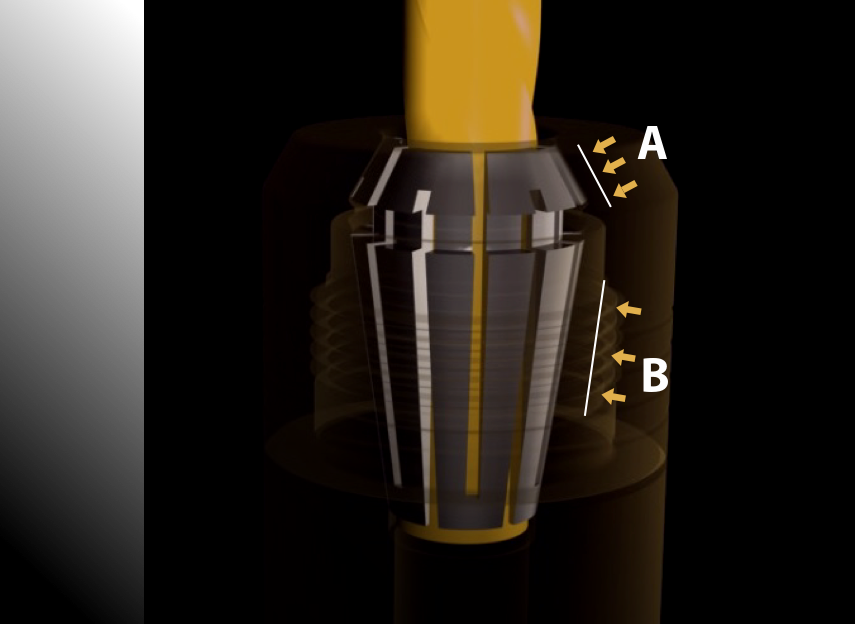

Stability / advantages of three-point two-sided clamping

Three-point and two-sided clamping: The clamping force is evenly distributed on the tool shank diameter. The clamping force of the HER system is evenly distributed on the A, B side single-sided clamping: The clamping force is only distributed on the B side. , The tool breaks inside the collet and damages the entire set of tool holders and collets.

Durability

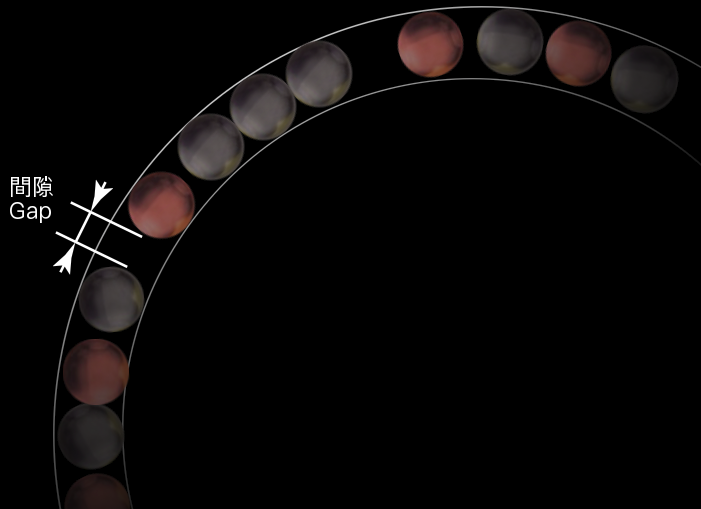

The steel balls are freely distributed, and there will be irregularities. When rotating at high speed, the imbalance will appear and there are restrictions on change. , Resulting in poor accuracy. There will be gaps in the assembly of the nut, and fine chips will invade from this gap, causing damage to the nut. Or under continuous use, cracking will occur.