Shrink Fit Chuck

Shrink Fit Chuck

Realize the dream of all-round ultra-high precision machining

The heat shrinkable clamping structure is adopted, and the inner hole is expanded by induction heating for tool clamping, and then cooled to achieve the clamping effect. In addition to maintaining reliable clamping performance at high speeds, reducing the outer diameter of the tool holder improves the anti-interference ability of the tool holder, and is especially suitable for high-speed milling processing with high speed and interference requirements.

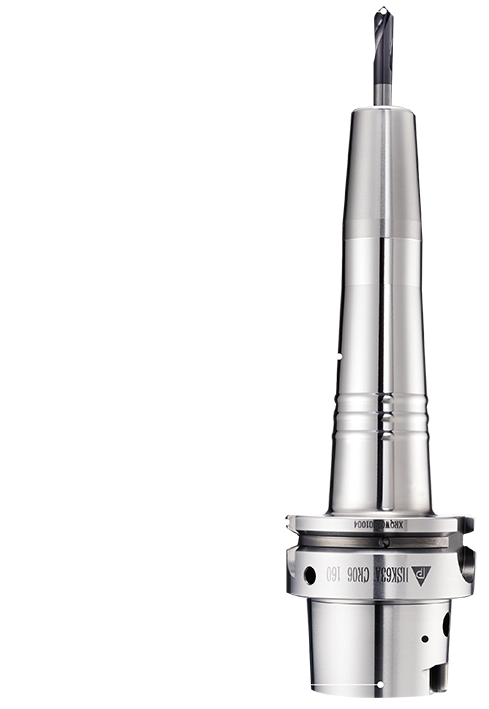

Good rigidity

CR standard type, one-piece meat thickness, super clamping force, rough and fine processing can be corresponded

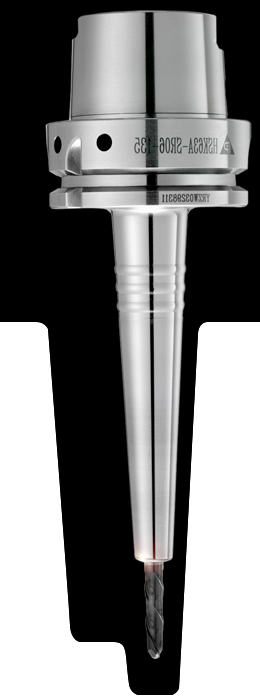

Overcome interference in deep hole machining

The SR slim type is more suitable for use in narrow spaces and corner interference problems

3µm high precision

Deflection runout≦0.003mm

Increase surface roughness to reduce tool wear

The accuracy measurement standard is 4 times the length of the tool shank diameter

Deflection runout≦0.003mm (4 times length)

Protect tool spindle and extend equipment life

After a special heat treatment process, the best accuracy and life can be maintained

Overcome interference processing

The SR slim type is more suitable for use in narrow spaces and corner interference problems

Heater Specification