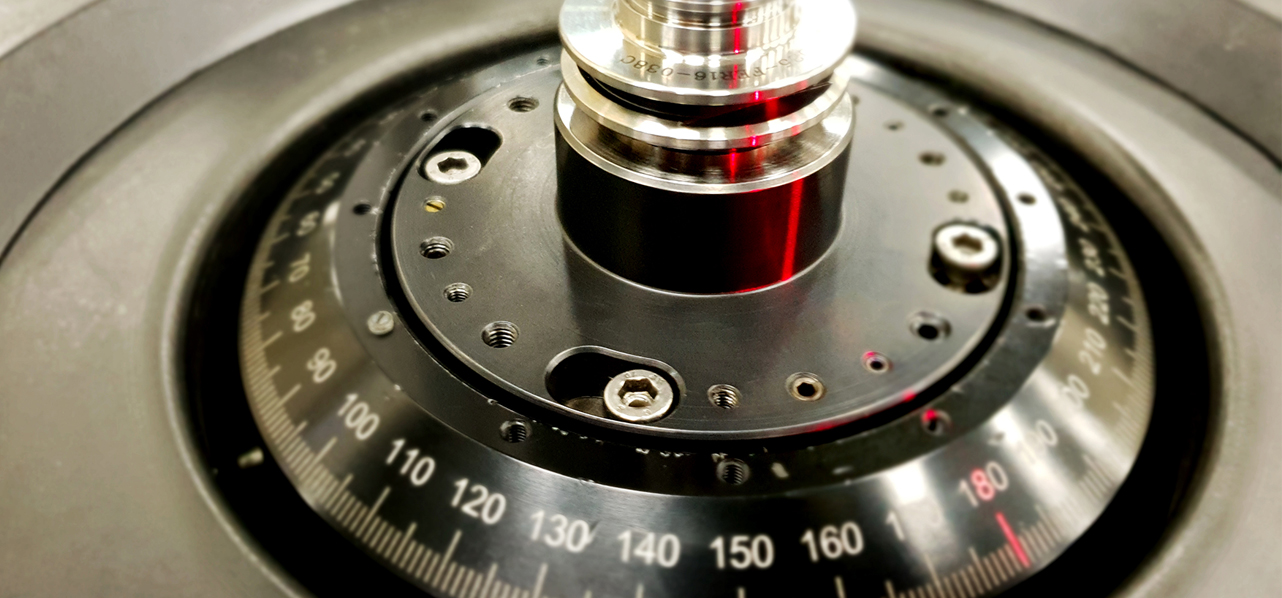

Heat & Special Treatments

Material handling

Without the right heat treatment method, no matter how high-grade materials and processing equipment are, it is impossible to achieve a tool holder with high precision and long life. The correct and excellent heat treatment can heat the material and rapidly quench it to obtain a high proportion of Asada loose iron, with excellent mechanical properties, including hardness, structure density, wear resistance, flexural strength, and tensile strength. On the contrary, the wrong or bad heat treatment caused the material itself to loose structure, uneven hardness, excessive residual internal stress, excessive residual austenitic iron, abnormal grain size and structure density, resulting in the mechanical properties not reaching the expected performance or even the material Phenomena such as deformation and cracking affect the most important accuracy and life of the tool holder.

Although PARFAITE adopts outsourcing in heat treatment, it adopts strict qualification screening and the policy of only seeking quality regardless of cost. We strictly select the best manufacturers across Taiwan for long-term cooperation, and review and improve with Japanese technical consultants from time to time. PARFAITE firmly believes that it is possible to manufacture products with precision and long life only by step-by-step, down-to-earth and not cutting corners.

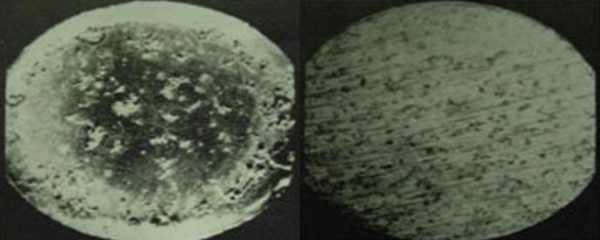

In addition, because the steel undergoes the quenching process, in addition to the production of loose iron, austenitic iron is also produced. In terms of organization, the residual austenitic iron belongs to an unstable organizational structure. Often due to the influence of external factors such as temperature and processing, the residual austenitic iron is transformed into hemp iron scattered due to energy, causing volume expansion, and then Produce size changes. After the steel is quenched, the residual austenitic iron content is between 2% and 30%. There are also as little as 0.15% and as much as 30%, depending on the steel grade and the degree of quenching. The existence of residual austenitic iron structure is a kind of unstable phase. The more the amount in the steel, the lower the hardness. It will cause dimensional changes due to temperature changes or phase changes during processing. Therefore, reducing the residual austenitic iron is Quite important, but it is necessary to prevent the austenitic iron from stabilizing during the quenching and cooling process, and it is necessary to increase the amount of loose iron produced in Asada, and improve the hardenability or reduce the quenching deformation. These goals are often difficult to achieve.

The above-mentioned material instability caused by the insufficiency of the heat treatment itself will cause the accuracy of the handle and other accuracy to change due to time... and other conditions. For the severity, please refer to the explanation of the accuracy of the handle. Therefore, the quality of ultra-precision tool holders such as hydraulic and HSK full series...etc. is also reached to the extreme. In addition to general heat treatment, Puhui also uses the most advanced special treatment technology to prevent the tool holder from deforming over the years and improve it. Wear resistance, increase hardness, uniform hardness, improve mechanical properties and expansion coordination.

Left: Metallographic structure before special treatment (the unstable structure of residual austenitic iron) / Right: Metallurgical structure after special treatment (remaining austenitic iron is transformed into Asada loose iron)