High Frequency Spindle

High Speed Spindle

Can achieve 3μ processing dream without expensive equipment

The accumulated accuracy from the rotating part to the tool end comes from Puhui's spindle and tool holder, with unified manufacturing and testing, high degree of integration of related accessories, and stable quality.

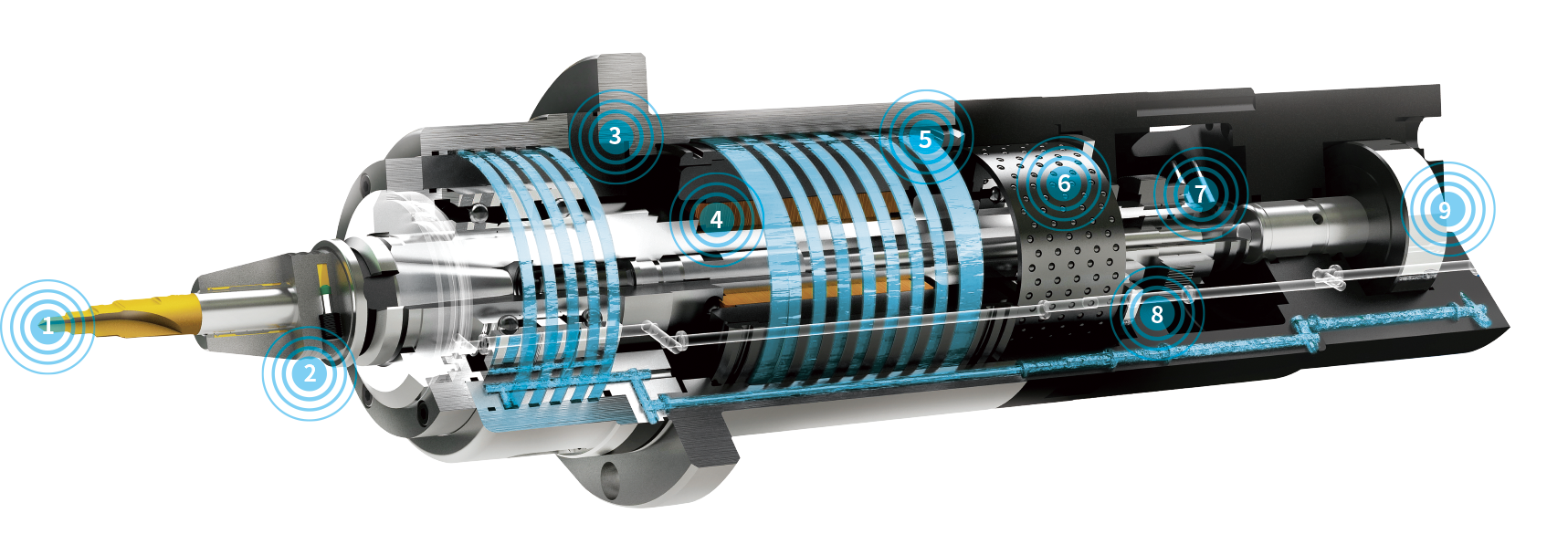

1. High repeatability

High Repeat Accuracy

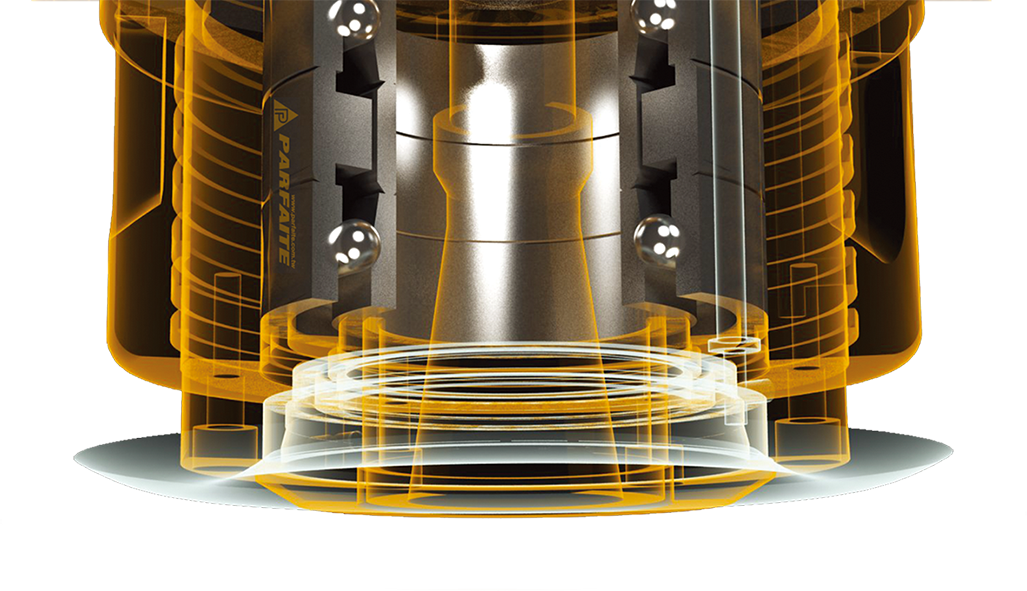

2. High clamping force

High Clamping Force

3. Air curtain protection

Air Seal

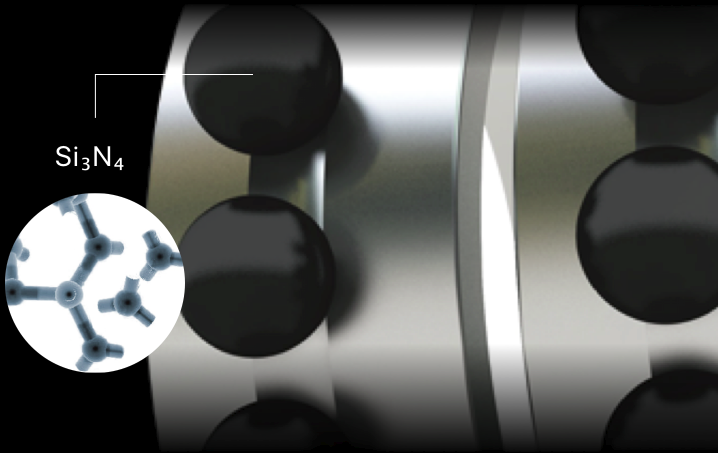

4. Ceramic ball bearing

Ceramic Bearings

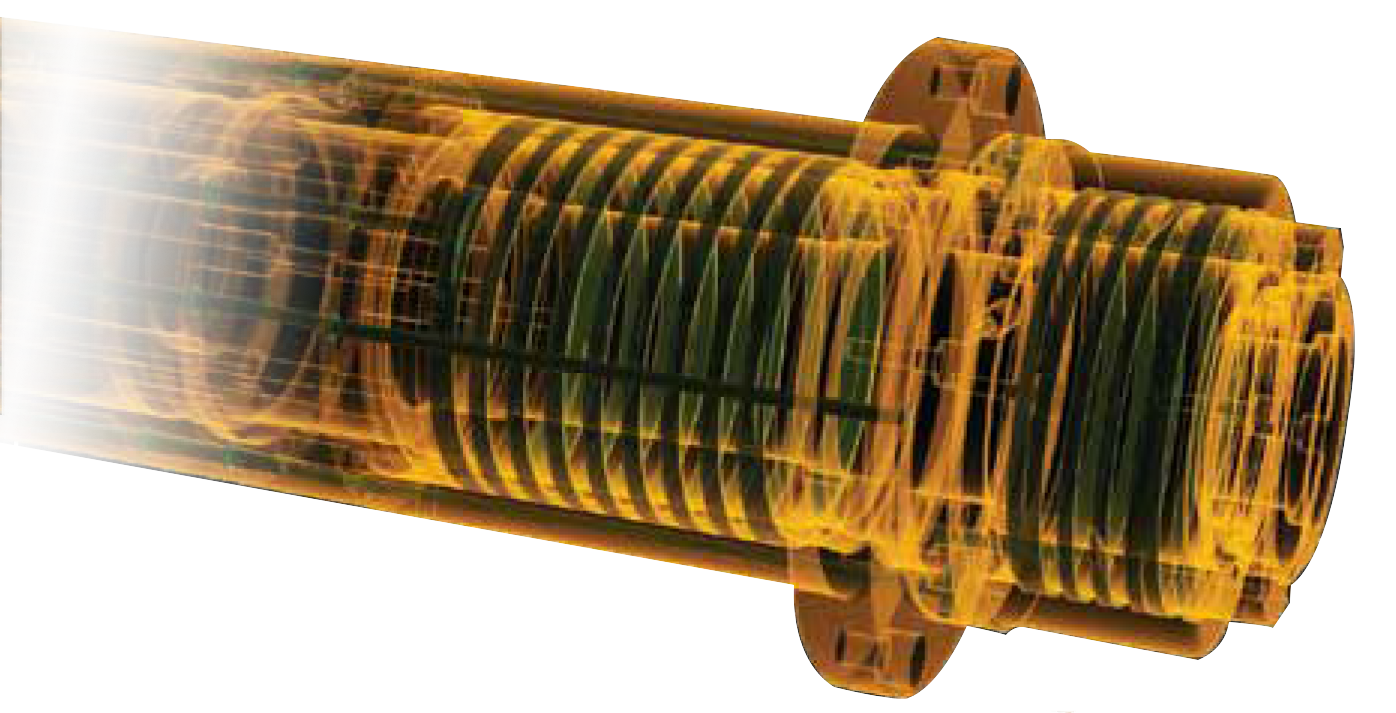

5. Annular cooling water circuit

Cooling Waterway

6. A retainer that stabilizes axial changes

Stabilizing Axial Displacement Cage

7. Knife Sensing

Approzimate Switch

8. Magnetic encoder

Magnetic Encoder

9. Knife cylinder

Clamping Cylinder

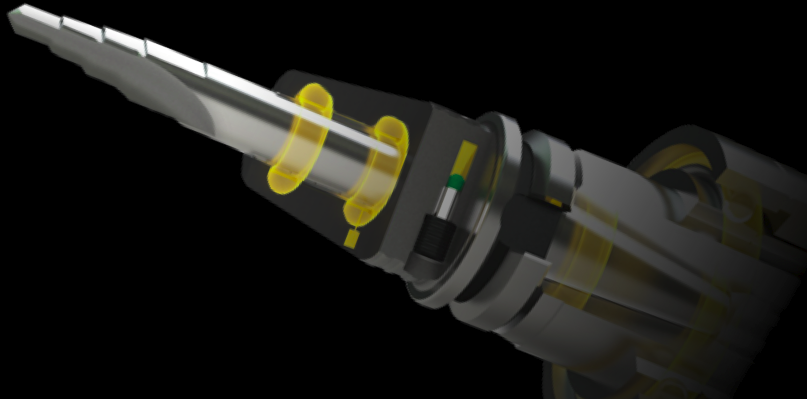

Two-sided support system

Attaching the taper and flange surfaces of the toolholder to the mandrel can increase the contact rate between the toolholder and the mandrel to 114%, which is more suitable for high-speed conditions than ordinary toolholders, which is beneficial to obtain more stable axial parallelism and strengthen dynamic speed The rigidity changes under.

High repeat accuracy

The accumulated accuracy from the rotating part to the tool end comes from Puhui's spindle and tool holder, with unified manufacturing and testing, high degree of integration of related accessories, and stable quality.

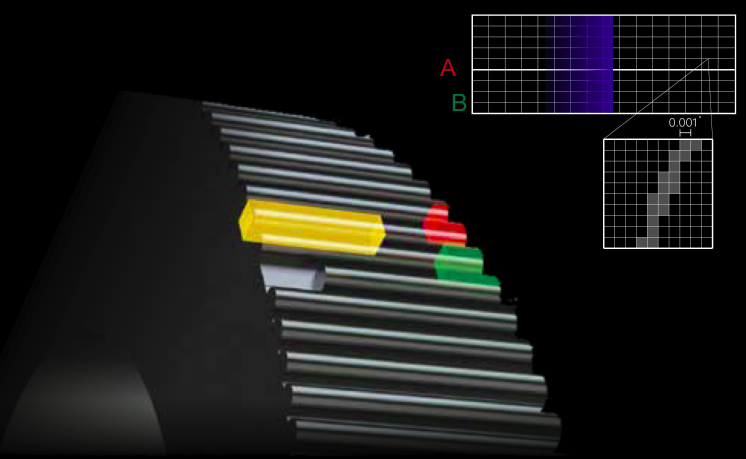

Magnetic encoder

The high-frequency encoder and high-precision gear enable the controller to correctly interpret the precise waveforms, which can greatly improve the stability of the spindle at high speeds, and make the low speed progressively smoother, with a resolution of 0.001°.

Precision Bevel Ceramic Ball Bearings

It adopts European P4S ultra-precision angular ball bearings. Compared with ordinary steel balls, the ceramic ball material is lighter, higher hardness, less unstable inertia, higher rigidity, and longer life. Not only the limit speed and cutting rigidity are greatly improved, but the cutting range of the spindle can be used more flexibly.

Annular cooling water circuit

The cooling water passes through the spindle's annular water path to uniformly cool the bearing and the motor heat source. In addition to keeping the spindle at a constant temperature, it can also reduce the tool end runout and improve the service life and accuracy.

Air curtain protection

The compressed air is transmitted to the air curtain ring, filling the clearance of the rotating parts and releasing air, so that the internal bearing is protected by positive pressure to prevent the intrusion of cutting water and foreign matter

Temperature sensor

Bearing temperature monitoring is actually very important. The front and rear bearings plus the basic motor temperature sensor are not only directly related to the service life of the spindle bearing, the temperature data will directly reflect the tolerance of the cutting load, and the abnormal temperature can make the equipment Give an early stop order to prevent burning. (Optional details have fixed models, please call for inquiries)

Full range of high-speed built-in spindle

Want to view all PARFAITE's high-speed built-in spindle products? PARFAITE provides all kinds of spindles to realize the full range of ultra-high precision machining dreams.