History

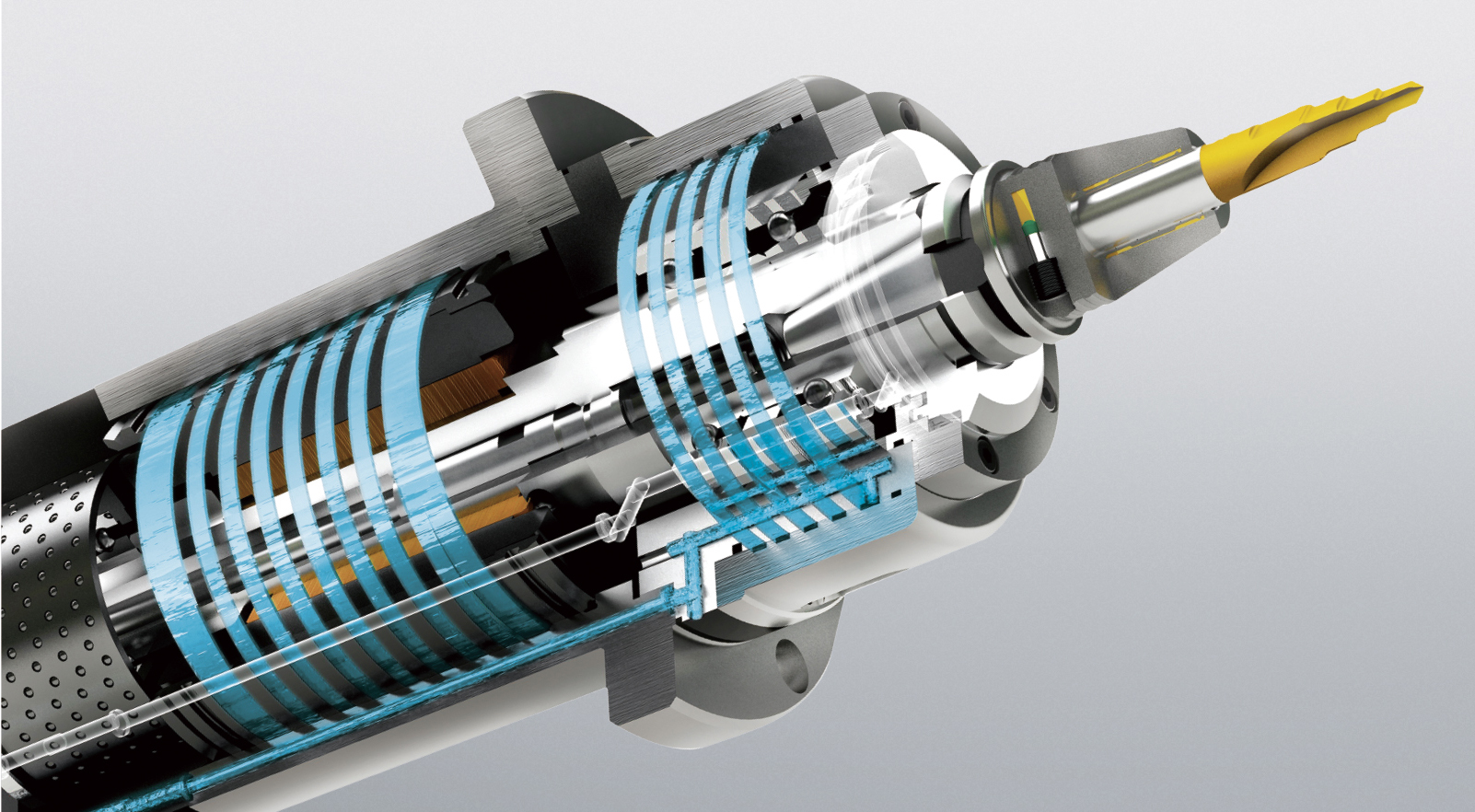

Established in 1982, PARFAITE Enterprise, based on nearly 40 years of mature and stable technology, specializes in the design, production and sales of high-speed motor built-in spindles, precision tool holders, and special tools. It is also the only company in the world that can produce this at the same time. A company with three high-quality technical products.

PARFAITE continues to lead the machinery industry with innovative technology for 40 years, constantly challenging the limit of industrial precision

PARFAITE focuses on the design and production of high-speed spindles, precision toolholders and special tools with built-in motors. It is also one of the few companies in the world that can produce these three high-quality technical products at the same time. To ensure customer quality as the highest indicator, we uphold the challenge The spirit of technological limit, constantly innovating and improving technology, looking forward to bringing the machinery industry to a new era.

1982 - 1990

PARFAITE was founded. From the deep cultivation of processing tools and investing in the development of knife handles, the cutting tool manufacturing technology is becoming more mature

PARFAITE Enterprise Co., Ltd. was founded. The products are mainly drilling tools such as bushings, collets, adjusting sleeves, multi-axis heads, fixtures, inspection fixtures, etc.

Factory settled in Tainan Anping Industrial Zone

The customer base is dominated by the automobile industry

Expand domestic business base and establish Taipei office

Expand production capacity and move to the current site of the Rende factory in Tainan

Tool holder specifications are mainly ER/side-fixed/mod taper/drill chuck

Dispatched several engineers to Japan to study tungsten steel tool making technology Obtained Taiwan's general agent of Fuji Seiko Co., Ltd.

1991 - 2000

Continuous innovation in the spindle field, entering the European and Japanese markets and planning to enter the field of tool holders

Set up Taichung office

Established Zhongli Office

The customer base is dominated by the automobile industry

Breaking through the technology monopoly of Europe and Japan, taking the lead in mass production, successfully developed Taiwan's first built-in high-speed spindle electric speed increaser, and successfully entered the US market

Started independent research and development of the built-in milling and engraving spindle project, and successfully entered the German market

Passed ISO-9002 international quality assurance certification

The knife handle business has entered the field of aerospace processing. OEM cooperation with many Japanese counterparts in special knife handles

Won the SME Innovation Research Award of the Ministry of Economic Affairs

The product line of knife handles adds hydraulic series and heat shrinkable series

2001 - 2010

PARFAITE Tool handles are stable and refined and are widely used in major processing plants, occupying a place in the field of precision processing

Established Shanghai branch and shipping center, and the knife handle business has expanded into 3C product fields such as chassis processing

Obtained Hanxiang Aviation AIDC S-200 certification to expand production capacity, increase capital and purchase new machinery to improve technical quality

Established Guangdong office and established Zhejiang office

Set up Wuxi Office Set up Tianjin Office

Established the Suzhou office in the global financial tsunami. Strengthened the mainland layout and established the Shenyang office

Opened Dalian Office

Started the new factory in Tainan

2011-2021

Start the capacity expansion plan. Expand the factory building, strengthen management, improve the production process, and lay out a wider market demand.

The second plant was completed and opened

The restaurant at the employee leisure center was completed and opened

Strengthen customer service in southwestern China and set up Wuhan office

Taipei TIMTOS Exhibition Announces Laser Assisted Cutting Spindle Technology

Started the rebuilding plan of the first factory, and moved some production lines to the third factory

The first plant operation headquarters was completed