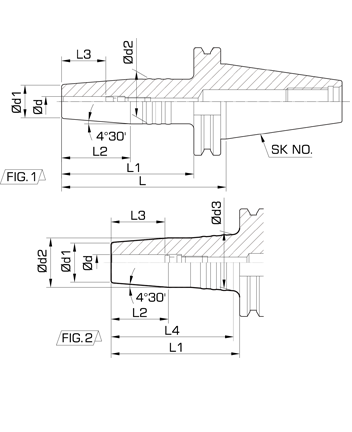

Dimensions

尺寸标示与详细规格比较

| Order No. 订购编号 | FIG | ∅d | ∅d1 | ∅d2 | ∅d3 | L | L1 | L2 | Tool Clamping Depth L3 刀具夹持深度 | L4 | Screw 调整螺丝 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SK40 CR04-080 | 1 | 4 | 16 | 23 | 80 | 60.9 | 40.7 | min18 | |||

| SK40 CR06-080 | 1 | 6 | 21 | 27 | 80 | 60.9 | 34.3 | 21.5~31.5 | HY06-M5 | ||

| SK40 CR06-130 | 2 | 6 | 21 | 27 | 31.9 | 130 | 110.9 | 38.1 | 21.5~31.5 | 108.1 | HY08-M6 |

| SK40 CR08-080 | 1 | 8 | 21 | 27 | 80 | 60.9 | 34.3 | 25.5~35.5 | HY08-M6 | ||

| SK40 CR08-130 | 2 | 8 | 21 | 27 | 31.9 | 130 | 110.9 | 38.1 | 25.5~35.5 | 108.1 | HY08-M6 |

| SK40 CR10-080 | 1 | 10 | 24 | 32 | 80 | 60.9 | 47 | 31.5~41.5 | HY08-M6 | ||

| SK40 CR10-130 | 2 | 10 | 24 | 32 | 31.9 | 130 | 110.9 | 50.8 | 31.5~41.5 | 108.1 | HY08-M6 |

| SK40 CR10-160 | 2 | 10 | 24 | 32 | 35.1 | 160 | 140.9 | 50.8 | 31.5~41.5 | 138.1 | HY08-M6 |

| SK40 CR12-080 | 1 | 12 | 24 | 32 | 80 | 60.9 | 47 | 36.5~46.5 | HY14-M8 | ||

| SK40 CR12-130 | 2 | 12 | 24 | 32 | 31.9 | 130 | 110.9 | 50.8 | 36.5~46.5 | 108.1 | HY14-M8 |

| SK40 CR12-160 | 2 | 12 | 24 | 32 | 35.1 | 160 | 140.9 | 50.8 | 36.5~46.5 | 138.1 | HY14-M8 |

| Order No. 订购编号 | FIG | ∅d | ∅d1 | ∅d2 | ∅d3 | L | L1 | L2 | Tool Clamping Depth L3 刀具夹持深度 | L4 | Screw 调整螺丝 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SK50 CR06-080 | 1 | 6 | 21 | 27 | 80 | 60.9 | 34.3 | 21.5~31.5 | HY06-M5 | ||

| SK50 CR06-130 | 2 | 6 | 21 | 27 | 31.4 | 130 | 110.9 | 38.1 | 21.5~31.5 | 103.3 | HY06-M5 |

| SK50 CR06-160 | 2 | 6 | 21 | 27 | 34.4 | 160 | 140.9 | 38.1 | 21.5~31.5 | 131.4 | HY06-M5 |

| SK50 CR08-080 | 1 | 8 | 21 | 27 | 80 | 60.9 | 34.3 | 25.5~35.5 | HY08-M6 | ||

| SK50 CR08-130 | 2 | 8 | 21 | 27 | 31.4 | 130 | 110.9 | 38.1 | 25.5~35.5 | 103.3 | HY08-M6 |

| SK50 CR08-160 | 2 | 8 | 21 | 27 | 34.4 | 160 | 140.9 | 38.1 | 25.5~35.5 | 131.4 | HY08-M6 |

| SK50 CR10-080 | 1 | 10 | 24 | 32 | 80 | 60.9 | 47 | 31.5~41.5 | HY08-M6 | ||

| SK50 CR10-130 | 2 | 10 | 24 | 32 | 31.4 | 130 | 110.9 | 50.8 | 31.5~41.5 | 103.3 | HY08-M6 |

| SK50 CR10-160 | 2 | 10 | 24 | 32 | 34.4 | 160 | 140.9 | 50.8 | 31.5~41.5 | 131.4 | HY08-M6 |

| SK50 CR12-080 | 1 | 12 | 24 | 32 | 80 | 60.9 | 47 | 36.5~46.5 | HY14-M8 | ||

| SK50 CR12-130 | 2 | 12 | 24 | 32 | 31.4 | 130 | 110.9 | 50.8 | 36.5~46.5 | 103.3 | HY14-M8 |

| SK50 CR12-160 | 2 | 12 | 24 | 32 | 34.4 | 160 | 140.9 | 50.8 | 36.5~46.5 | 131.4 | HY14-M8 |

备注Remarks

- 刀具柄径公差h6( h6 Tooling Diameter Tolerance)

- 若需出水型刀把,请参考选用说明