Page 14 - 襯套

P. 14

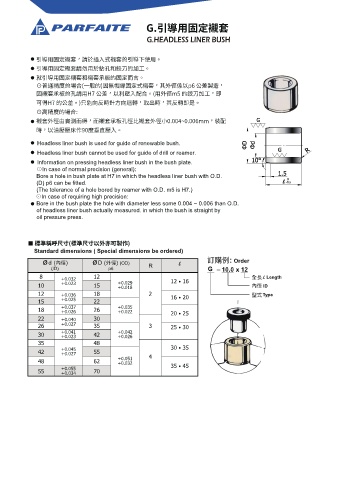

G.引導用固定襯套

G.HEADLESS LINER BUSH

● 引導用固定襯套,請於插入式襯套的引導下使用。

● 引導用固定襯套請勿用於鉆孔和鉸刀的加工。

● 就引導用固定襯套和襯套承板的固定而言。

⊙普通精度的場合(一般的)因無帽緣固定式襯套,其外徑係以p6 公差製造,

固襯套承板的孔請用H7 公差,以利壓入配合。(用外徑m5 的鉸刀加工,即

可得H7 的公差。)只能向反時針方向迴轉,取出時,其反轉即是。

⊙高精度的場合:

● 襯套外徑由實測而得,而襯套承板孔徑比襯套外徑小0.004~0.006mm,裝配

時,以油壓壓床作90度垂直壓入。

● Headless liner bush is used for guide of renewable bush.

● Headless liner bush cannot be used for guide of drill or reamer.

● Information on pressing headless liner bush in the bush plate.

ôIn case of normal precision (general):

Bore a hole in bush plate at H7 in which the headless liner bush with O.D.

(D) p6 can be fitted.

(The tolerance of a hole bored by reamer with O.D. m5 is H7.)

ôIn case of requiring high precision:

● Bore in the bush plate the hole with diameter less some 0.004 ~ 0.006 than O.D.

of headless liner bush actually measured. in which the bush is straight by

oil pressure press.

標準稱呼尺寸(標準尺寸以外亦可製作)

Standard dimensions ( Special dimensions be ordered)

ød (內徑) øD (外徑) (OD) l 訂購例: Order

(ID) p6 R G – 10.0 x 12

8 +0.032 12 全長 l Length

10 +0.023 15 +0.029 12˙16 內徑 ID

+0.018

12 +0.036 18 2 16˙20 型式 Type

15 +0.025 22

18 +0.037 26 +0.035 20˙25

+0.022

+0.026

22 +0.040 30

26 +0.027 35 3 25˙30

30 +0.041 42 +0.042

+0.026

+0.023

35 48 30˙35

42 +0.045 55 4

+0.027

48 62 +0.051 35˙45

+0.032

55 +0.055 70

+0.034